Paperchef

How do you overhaul a manufacturer’s 40-year-old software to streamline operations during a relocation?

Product Strategy

User Experiencie Design

Visual Design

LMS

Web Development

The Challenge

Old work-arounds had become status quo. This made for a lot of redundant work, virtually-impossible employee onboarding, and timely data a distant dream. Our first mission was in an advisory role, auditing their existing stack, documenting their work flows, and interviewing stakeholders to figure out what was possible without fully interrupting operations.

We determined the new system needed to a) have enough data and features to bring them up to speed and b) be lightweight enough to ensure their system could still have a competitive advantage over other companies of similar size. Paperchef had previous quotes for ERP systems in the multi-million dollar range. We knew we could saddle up, ride into town and build them something better for less. It wasn’t exactly the wild West (more like the wild North of Toronto), but it did feel like an adventure. Hence why we named our new custom ERP, Wyatt (as in Erp, the infamous lawman of Tombstone).

Our Solutions

01

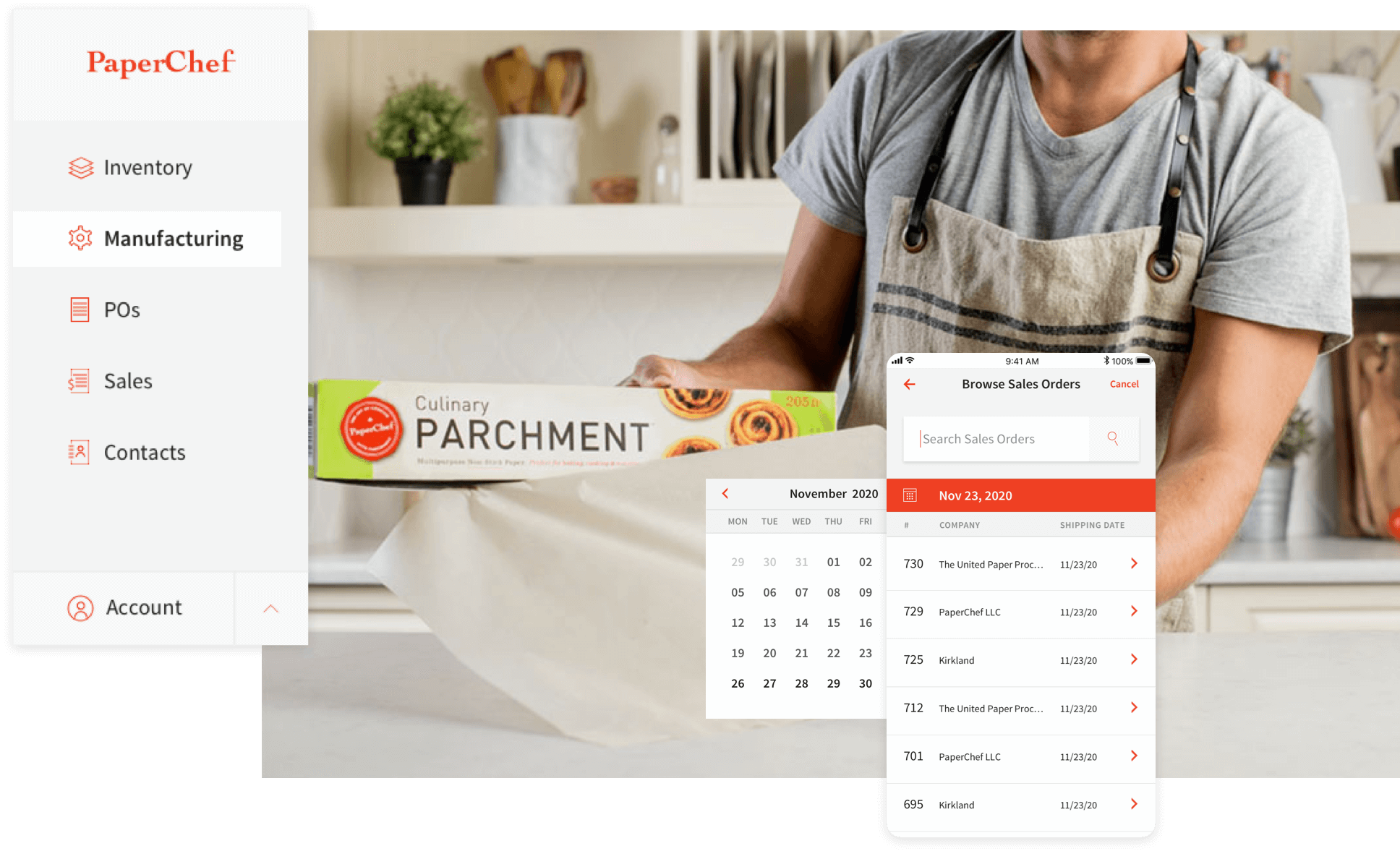

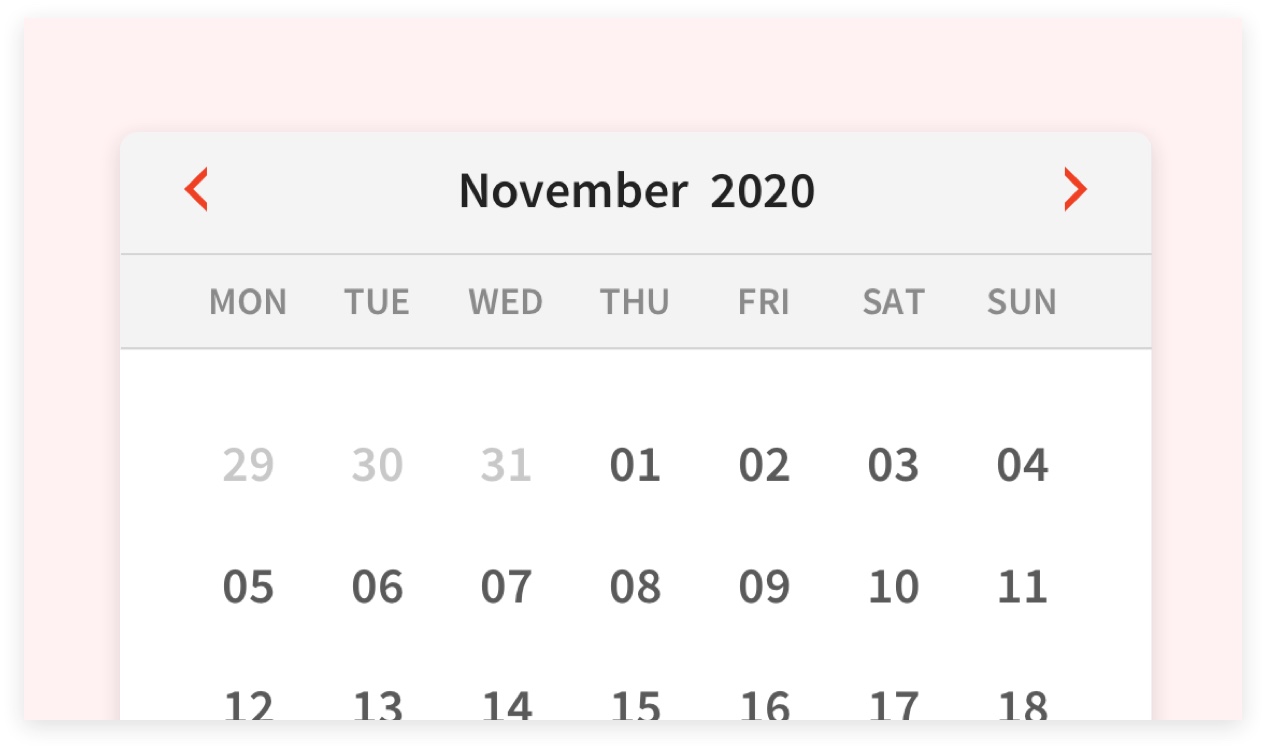

Design that scales

Design that scales

We developed Wyatt (our ERP) to meet Paperchef’s specific work-flow demands with enough flexibility to keep up with their growth.

We developed Wyatt (our ERP) to meet Paperchef’s specific work-flow demands with enough flexibility to keep up with their growth.

The design was strategic: Make it way easier to use than other ERP systems, but with the ability to easily add features and evolve when necessary. We used the feedback of 30+ beta users at the Toronto factory to perfect the flows and ensure they could do everything they needed (and more).

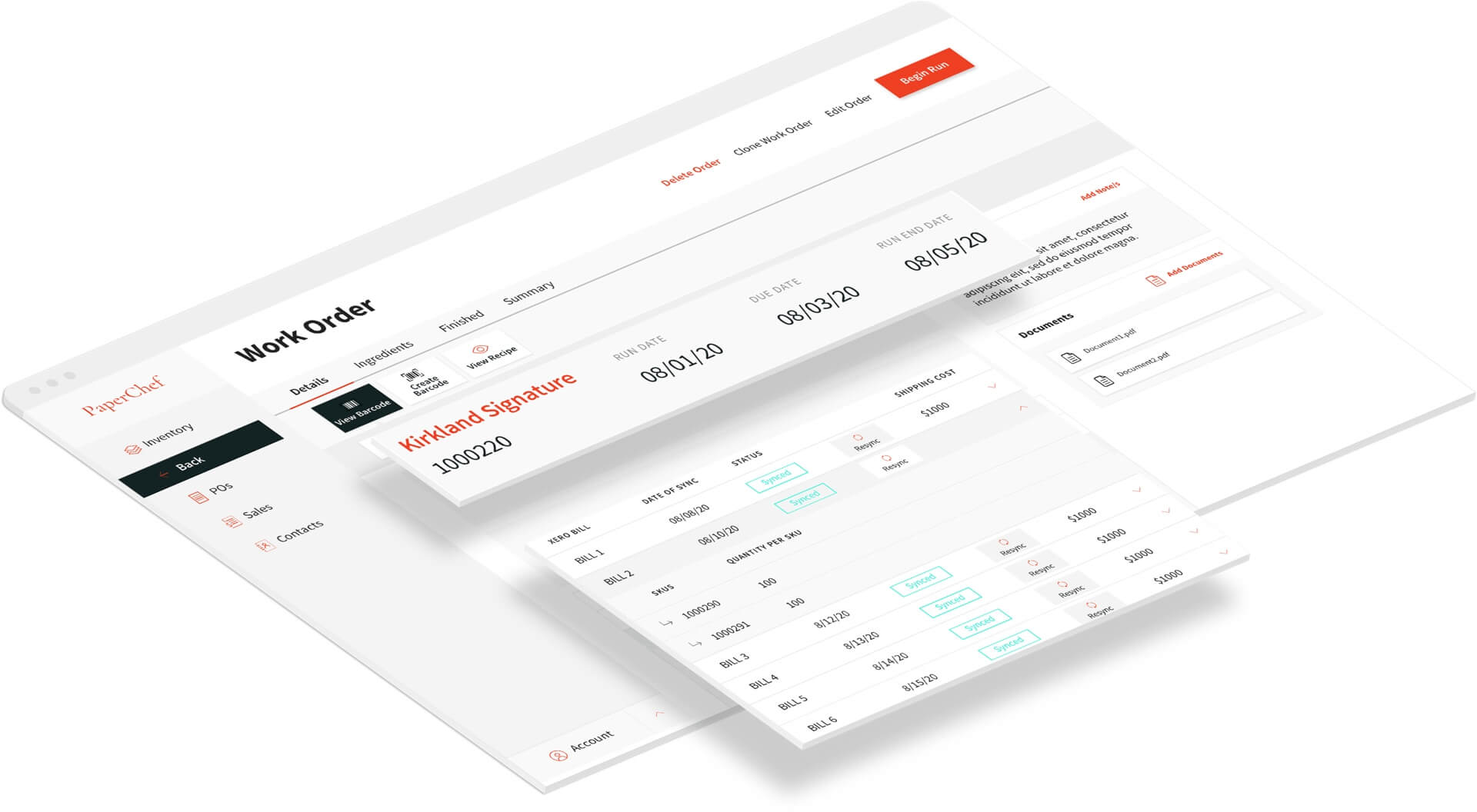

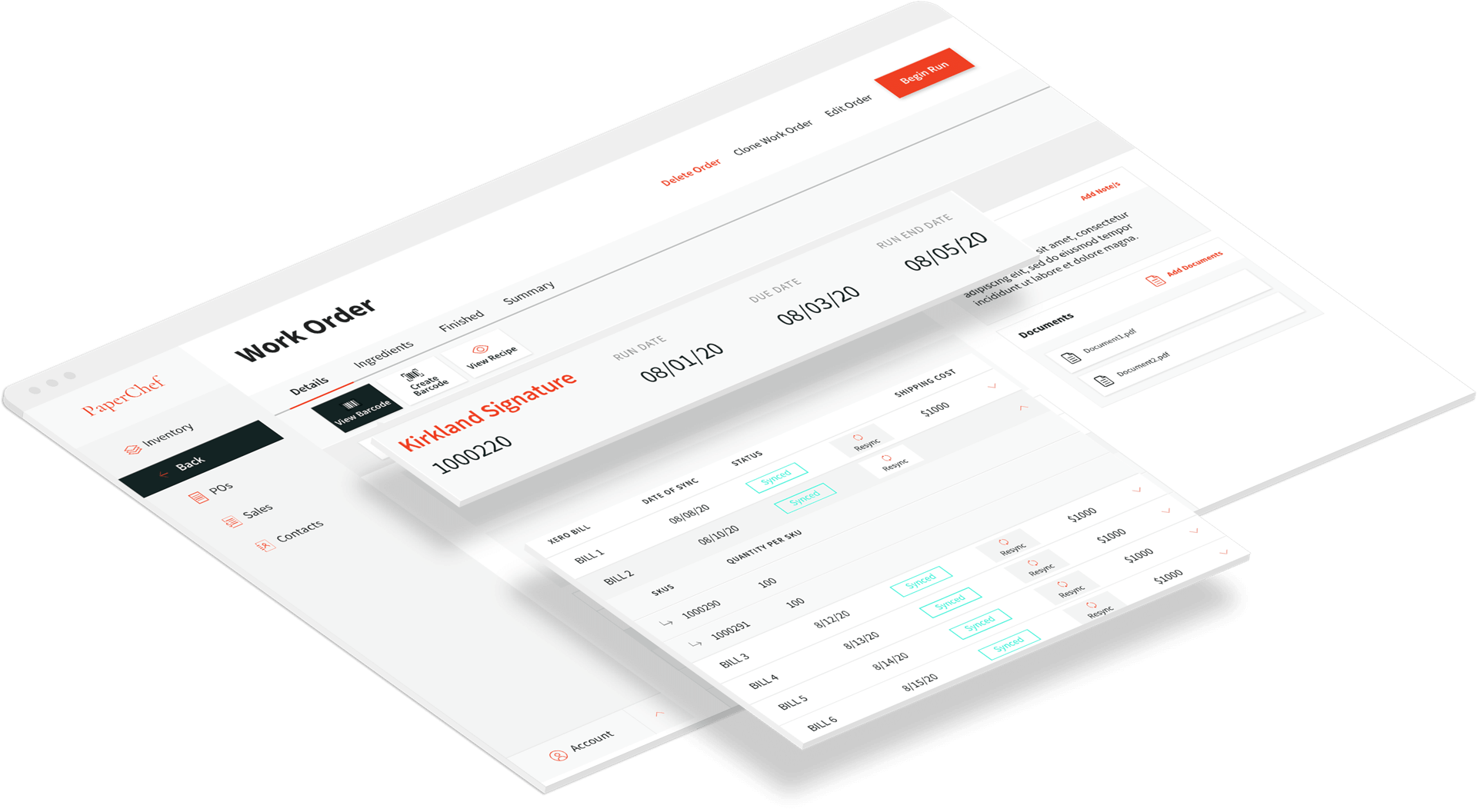

02

Access to fast,

reliable data

Access to fast, reliable data

A robust API and EDI capabilities paired with powerful reporting tools made long-term planning a real thing.

A robust API and EDI capabilities paired with powerful reporting tools made long-term planning a real thing.

We built a fast, efficient and clean codebase using Rails and React from scratch that could support lots of inventory turnover and could reverse integrate with pretty much anything. Wyatt didn’t need to reinvent the wheel on reporting, so we built it to easily work seamlessly with third-party BI tools like AWS Quicksights—a low-cost, ultra user-friendly service that offers lots of customization for reports. Paired together, the Paperchef team can access real-time intel on their inventory from any desktop, phone, or tablet. Which was good, because shortly after launching, we packed up the ranch and moved the entire operation across the border to Nashville TN.

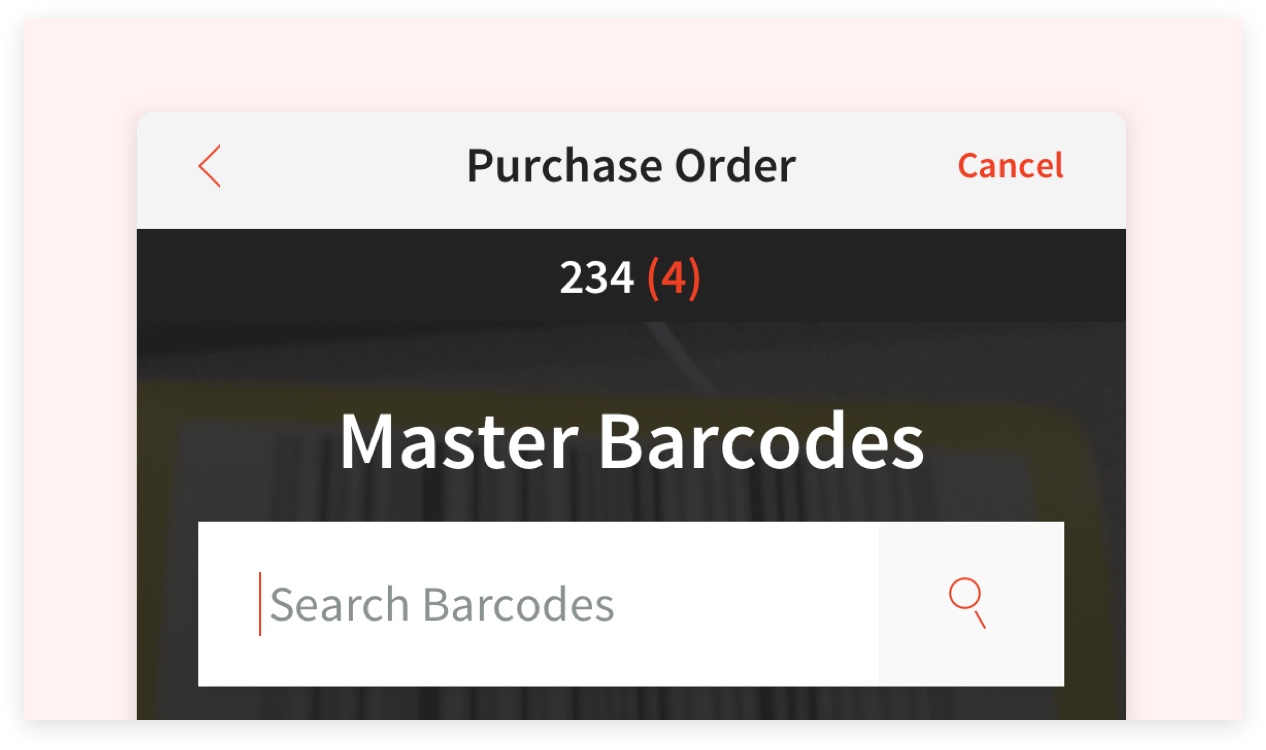

03

Ultra-simple,

speedy setup

Ultra-simple, speedy setup

Wyatt runs on best-in-class consumer-grade hardware that is simple to use, maintain, and replace.

Wyatt runs on best-in-class consumer-grade hardware that is simple to use, maintain, and replace.

This ensured our ERP (“Wyatt”) was a fraction of the cost because it didn’t come with the proprietary tools that are required with other ERP systems. We swapped Paperchef's pricey terminals, outdated printers, and temperamental scanners for affordable desktop computers, streamlined label printers, and smart phones with Wyatt's Android app downloaded and ready for use. If they needed new hardware, most of our gear could be sourced the same day. A good thing if you’re planning on opening up a brand new HQ (in the middle of a pandemic).

04

On-site launch and

support

On-site launch and support

Hands-on training, testing, and implementation allowed us to get their massive warehouse up and running in a single weekend.

Hands-on training, testing, and implementation allowed us to get their massive warehouse up and running in a single weekend.

A fancy ERP is only useful when people actually know how to use it. The eight-month dev and design build culminated in a two-week test launch to find critical bugs and then a single-weekend implementation of the full product where we were onsite to train managers, answer questions, and wrangle the tech. It isn’t easy transitioning from 40-year-old systems, but together with the Paperchef team, we got every single piece of inventory counted and relabeled, relocated to the right spot, data rolled over to the new system, and got orders back on the manufacturing line in less than three days.

Our lightweight, custom ERP completely replaced Paperchef’s outdated sales, inventory, shipping, and tracking systems--modernizing their Toronto factory and ensuring their new US warehouse could open in record time.

Average Hardware Cost per-unit

Items Inventoried at Launch

Current Inventory Items

Wyatt is an ERP like no other. Taking inventory stock is much less labor intensive, and the right people have access to the right data whenever they need it. Work orders are easier to track and hardware is easier to replace. Engineered specifically for the Paperchef Toronto team, it can do lots of very special and specific things. But we wanted it to be able to plug in anywhere.

When the company decided to move their warehouse to Nashville, TN in the middle of a pandemic, the one thing they didn’t have to worry about was their ERP. We helped customize codes to fit the new warehouse and they were up and running in a matter of days. Yeehaw.

Curious about improving your current ERP?

We're currently developing a lightweight product that is the perfect fit for small and mid-size companies that need a more flexible way to manage their manufacturing.